Text contenSRM screw compressors has totally changed the refrigeration industry and global leading companies such as Howden, Myekawa, Frick and Fujian Snowman use SRM screw compressor technology.

SRM has during the years designed 1-stage, 2-stage and semi hermetic compressors for various applications for the refrigeration industry. There are many different design options which all have different pros and cons.

Within the Asian refrigeration industry there has been a trend since many years to use 2-stage compressors instead of separate booster compressors, which is a more common trend in Europe and in the US. The 2-stage compressors are always a more compact solution for achieving low temperature refrigeration. Starting from pressure ratios beyond 10 -15 the 2-stage compressor gains efficiency against the 1-stage compressor. As 2-stage compressors usually are adapted for low temperature freezing in the range of -50 to -60 deg C and the corresponding pressure ratio is in the range of 20 – 40, the benefit of 2-stage solution is even more obvious.

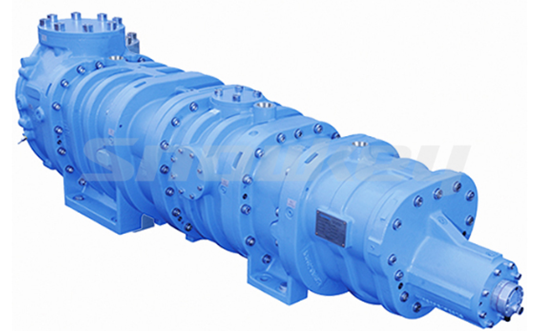

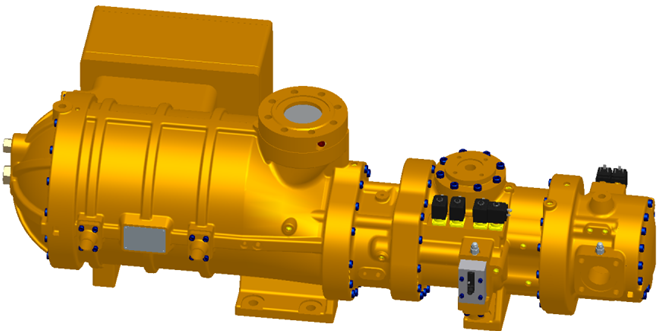

In the current range of 2-stage compressors developed, the largest models are of open type while the smaller ones are of semi hermetic type. The compressors are designed for operation with ammonia as well as synthetic refrigerants.

Want to know more?

Please contact Mats Sundström | +46 (0) 70 611 45 54 | mats.sundstrom@rotor.se